Renowned for its high sustainability standards, Steinfels Swiss is one of the leading suppliers of cosmetics, detergents, and cleaning and hygiene products. The most prestigious national and international companies rely on Steinfels Swiss’s experience and expertise to guarantee the highest quality products and services. Based in Winterthur, Steinfels Swiss develops and manufactures innovative solutions in a sustainable manner throughout the entire value creation process, distributing them globally. Steinfels Swiss is part of the Coop Group.

Its strength lies in innovation, sustainability, and Swiss quality. The company works closely with its customers to develop and launch innovative concepts, products, and services at the right time. With over 20 years’ experience in providing sustainable solutions for cleaning, hygiene, personal care and cosmetics, Steinfels Swiss continues to refine its processes to meet the most demanding standards. They guarantee maximum quality and reliability by carrying out all development and production exclusively in Winterthur, Switzerland.

Innovation in action: format changeovers in less than 5 minutes

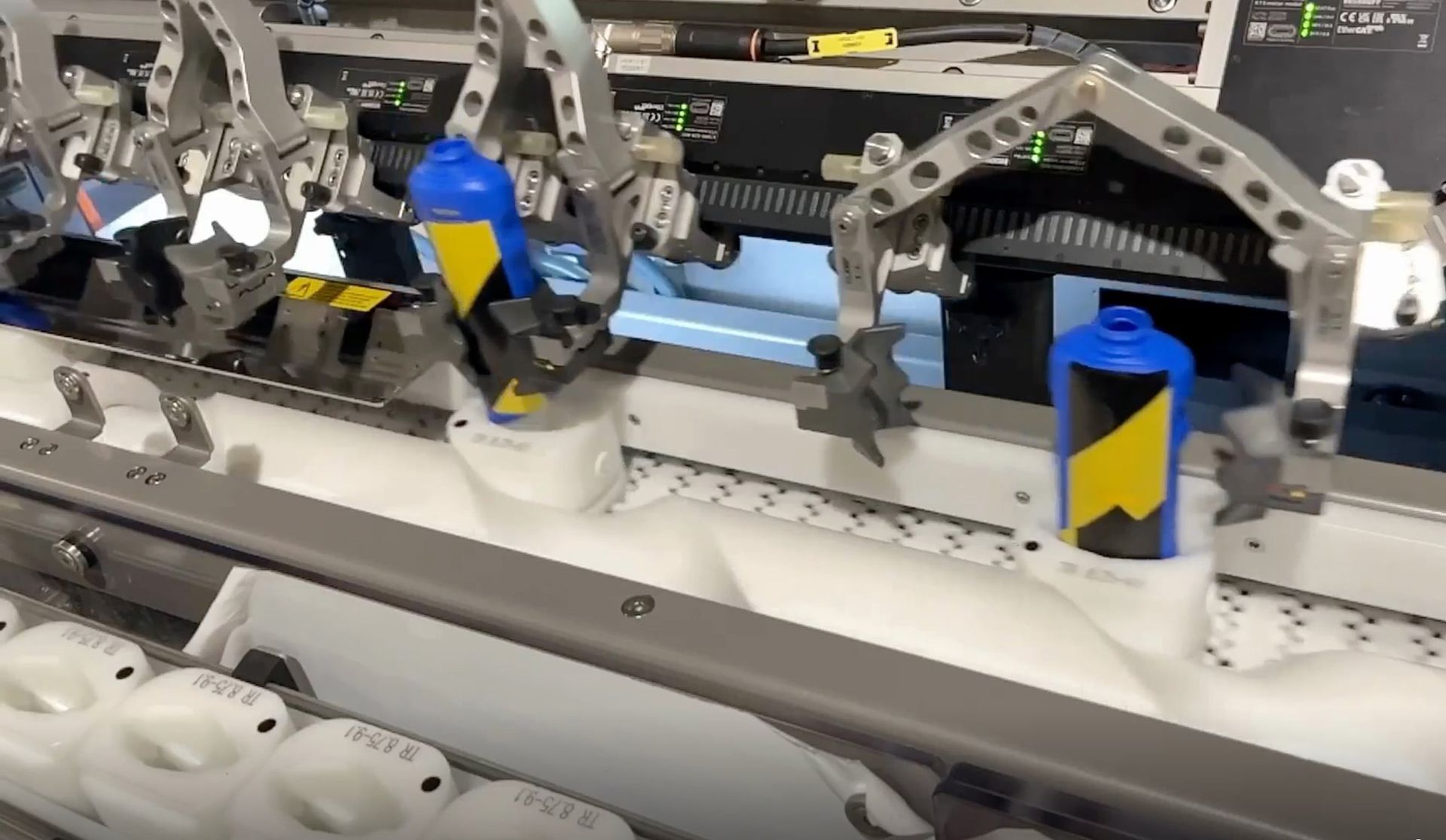

When the Steinfels Swiss team first contacted Packfeeder for this new project of a multiformat container unscrambler with pucks, it seemed difficult to believe the magnitude of the requirement. They needed to be able to produce 52 different container formats on the packaging line!

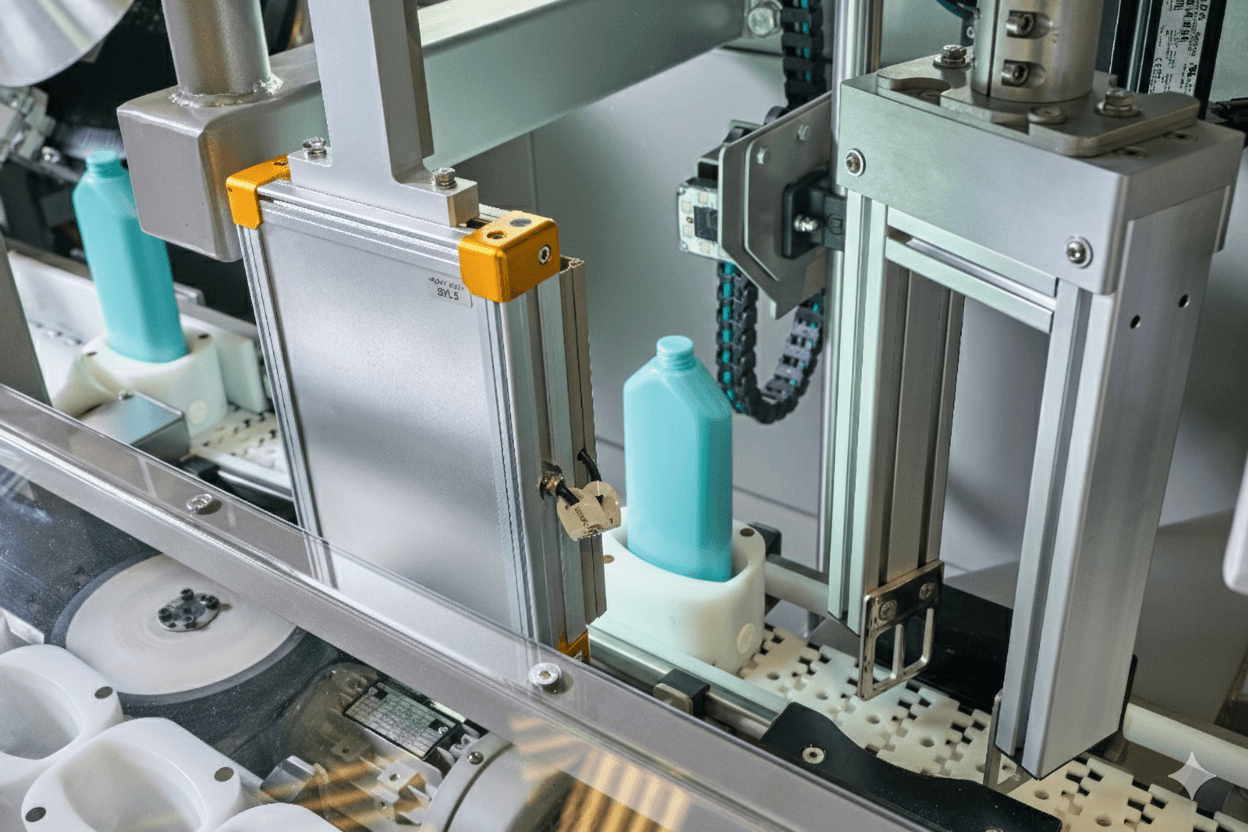

After confirming the customer’s need to install container orientation equipment in their plant, the Terrassa-based company’s team began internal studies. These led to an agreement with the Swiss manufacturer to install a robotic container feeder with an additional bottle-orienting function for asymmetrical containers.

The biggest challenge of the project was not the required production speed in terms of containers per minute. Nor was it the characteristics of the complete system, which included a pre-feeding hopper in the warehouse, overhead conveyors, an unscrambling system, an orientation module and special conveyors that allow glass products to be loaded manually without compromising the compact and functional layout of the pickFeeder.

The main problem was the huge variety of containers that the customer needed to process in the machine to correctly feed their packaging line, with format changes taking less than five minutes and carried out by unqualified employees. The same system had to unscramble containers of different shapes, volumes, materials and types.

The results speak for themselves: maximum flexibility and agility

After months of project execution, a successful FAT was carried out with the customer, demonstrating the system’s optimal performance for a sample of less than 20 containers. The customer introduced the rest of the bottles with the help of Packfeeder experts after receiving intensive training at the Winterthur facility in Switzerland.

This clearly demonstrated the enormous potential and capacity of the multiformat robotic container positioning technology developed by Packfeeder to address real production challenges requiring a level of flexibility that is unimaginable with other types of technology.

For this project with Steinfels, the choice of highly flexible container unscrambling technology, such as that offered by the pickFeeder series, was crucial.

Packfeeder’s technical team is at the disposal of all manufacturers facing packaging challenges due to the large number of different formats on the line to discuss each case in detail and offer the container orientation solution that best solves your problem, whether that be robotic bottle unscrambling technology or a simpler alternative.

Want to optimize your packaging line like Steinfels Swiss?

At Packfeeder, we provide customized solutions that enhance efficiency and precision in bottle unscrambling.

Contact us so we can review your case together and offer the best option for your packaging line.