ROBOTIC

BOTTLE UNSCRAMBLER

PICKFEEDER SERIES

The most flexible

bottle sorting solution

bottle sorting solution

VERSATILITY TAKEN

TO THE NEXT LEVEL

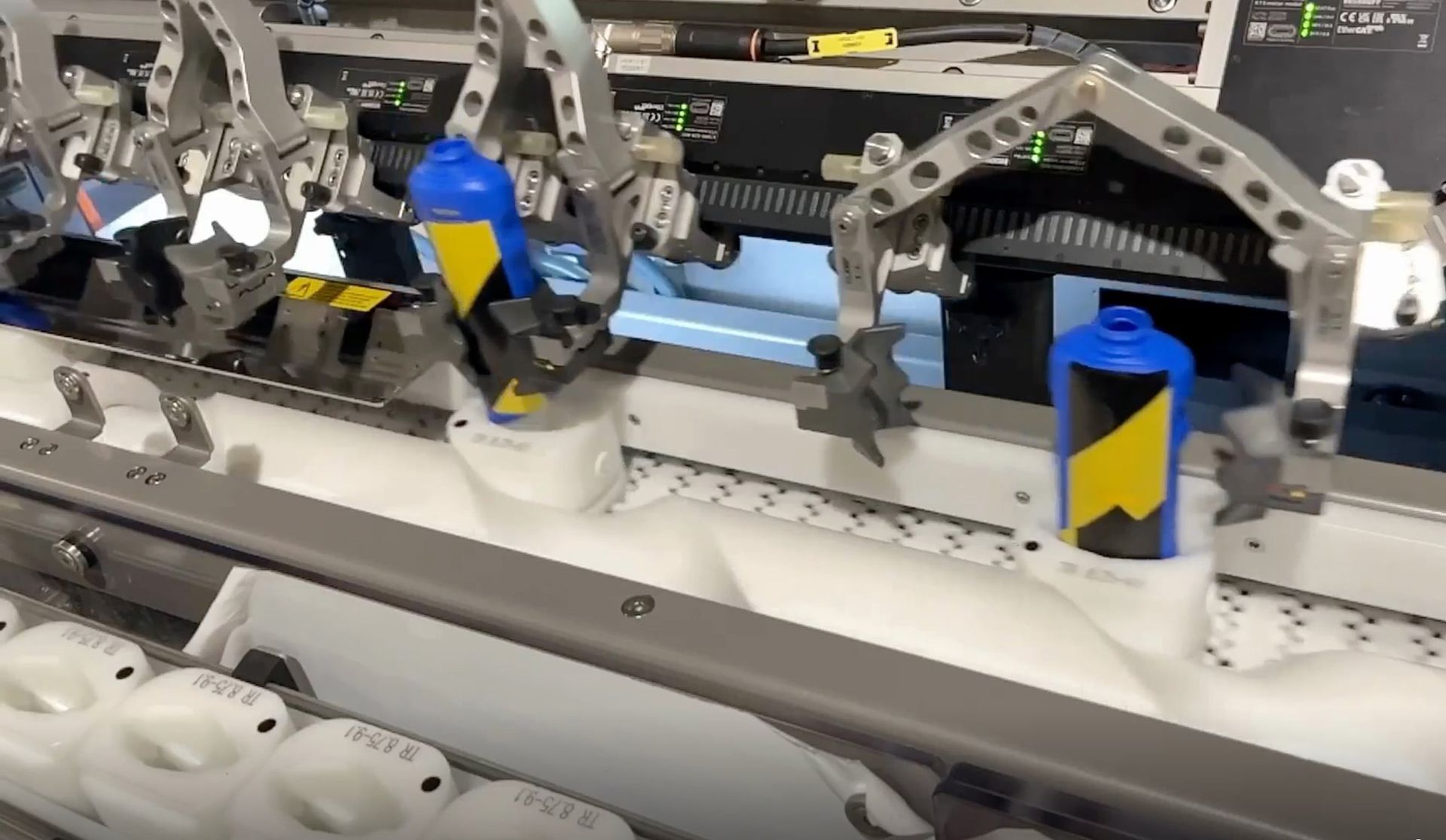

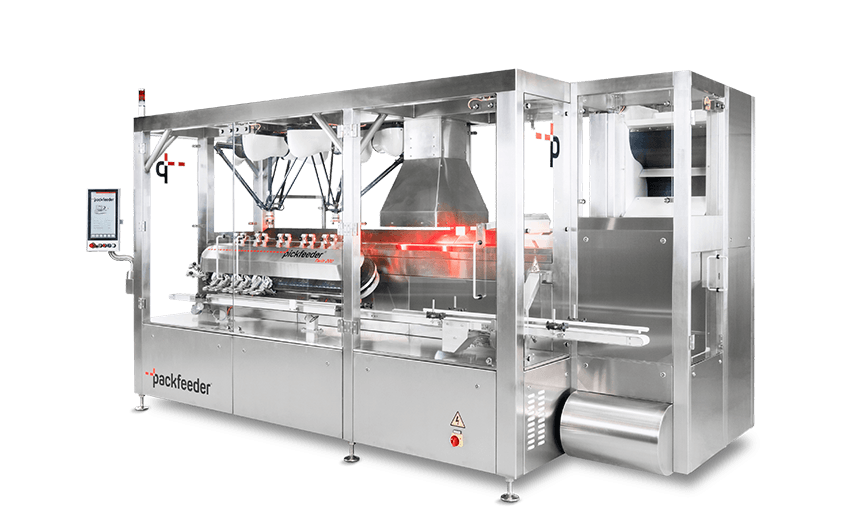

Once again, the Packfeeder team manages to go one step further in the world of container unscrambling by developing the pickFeeder series. This robotic container unscrambler, configurable with one, two, three or even four robots, offers a wide range of applications and possibilities. Our combination of delta robots with an intelligent track system makes the Pickfeeder the most versatile automatic changeover machine on the market, optimising the performance of the intelligent systems that make it up and guaranteeing the stability of the containers delivered to the line.

WHAT SETS US

APART

Maximum versatility

Immediate format changeover

New formats, cost 0

Do It Yourself

Permanent bottle vision

Extreme care of the container

Boosted productivity per m2

Taylor made solutions

WHICH OF YOUR

NEEDS WE SOLVE?

Flexibility

Our robotic bottle unscrambler system stands out for its unparalleled flexibility, capable of handling an infinite variety of products. This system is meticulously designed to be customised to the specific needs of each production line, ensuring optimal performance and efficiency. Its great adaptability allows it to work seamlessly with any container, geometry and material, achieving almost zero downtime for format changeovers and maximising productivity.

Multifunction capabilities

In addition to container unscrambling, various other functions can be added to optimize the production line. Some of these functions include: labelling, track & trace, inkjet, laser coding, rinsing, inspection, filling… These capabilities enable complete process automation, ensuring faster, more accurate, and consistent production, tailored to the specific needs of each production line.

Unmatched OEE

When availability, performance and quality are optimised, the result is unparalleled Overall Equipment Effectiveness (OEE). Achieving this means that the line is operating at its peak potential, increasing production rates while reducing costs and improving overall competitiveness in the market. This high performance is due to our patented technology based on high-speed robots and precise bottle transfer thanks to the implementation of magnetic carousel technology.

MUCH MORE

THAN UNSCRAMBLING

ORIENTATION

PUCK INTRODUCTION

CLEANING SYSTEMS

TRACK & TRACE

LASER CODING

INKJET CODING

INSPECTION

LABELLING

SPECIFIC SOLUTIONS

FOR EACH INDUSTRY

All our know-how at the service of your packaging lines.