5 years ago, thanks to the constant aim of innovating in the packaging industry, the Packfeeder’s team presented the robotic unscrambler for containers with 1-2-3-4-5 robots. What started in that moment, has already been consolidated both in the version with delivery to a classic conveyor and in the version with delivery and placement in pucks.

Especially this latest development of the Packfeeder’s team is the adaptation of our pickFeeder robotic unscramblers to lines that work with pucks system. As it couldn’t be otherwise, all the characteristics and advantages of the pickFeeder Series range have been maintained:

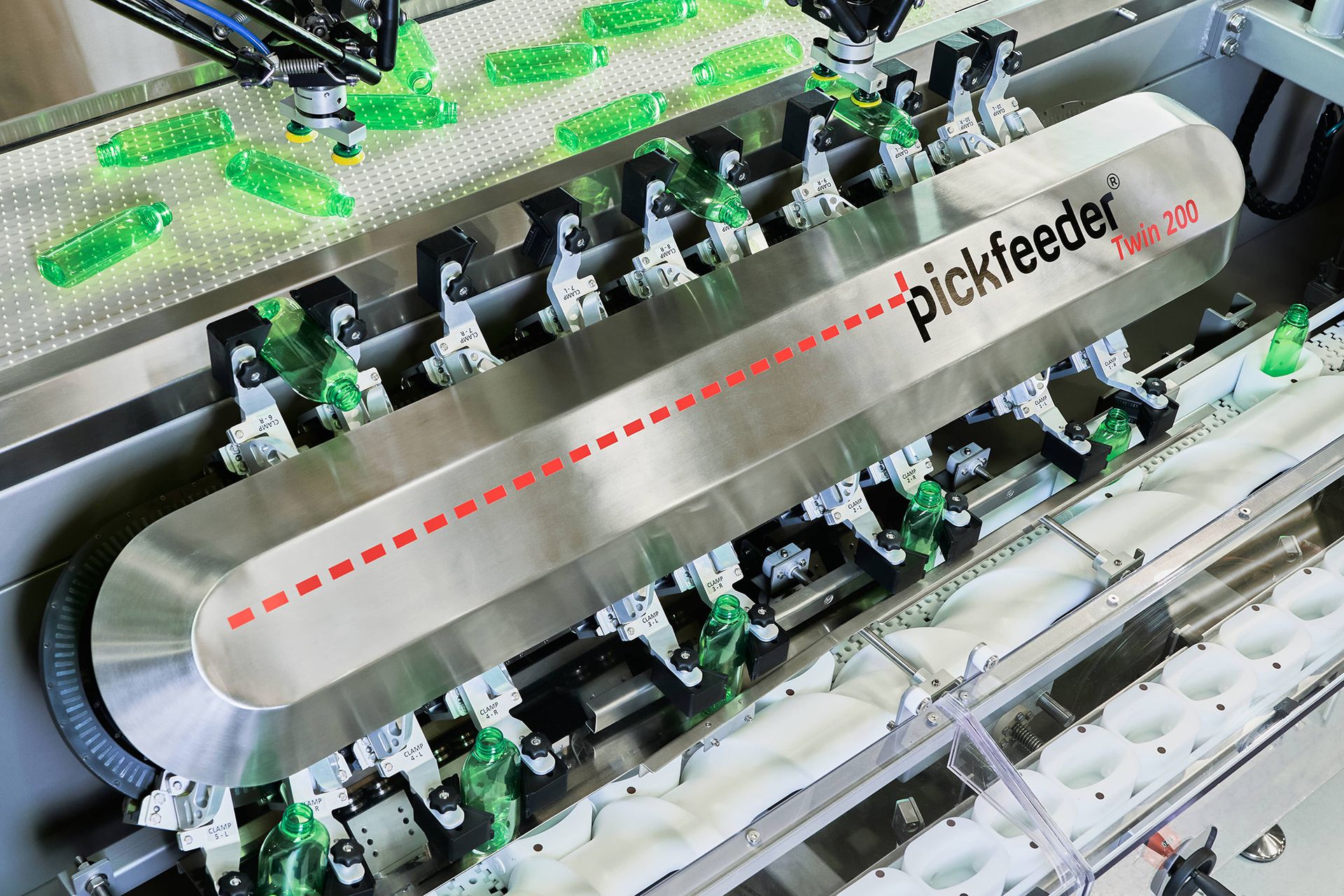

- It is a highly versatile system for present and future needs. In its design, flexibility has been considered as the main criterion, from the introduction of containers in the hopper until they come out through the exit conveyor. Each of the elements that participate in the process are prepared to be flexible for facing future unknown needs. The robots take the containers in a horizontal position, the intelligent carousel picks up the containers and carefully inserts them into the pucks.

- Precise and efficient puck positioning concept. The picking process done by the robots is separated from the process of introduction into the pucks. As the two functions are separated, any hypothetical limitation of robots’ vacuum grippers would not affect the efficiency of the pucks system. By transferring the containers from the robots to the intelligent carousel we are recentering them, eliminating any possible deviation coming from the robots or the vision system. That is why the introduction of the containers into pucks can be carried out with such high precision.

- Increase of the productivity per m2. The availability of space is a common limitation among packaging plants. So, maintaining a reduced layout while ensuring access and ergonomics are key aspects, not only for the installation of the equipment but also for its operation. Thanks to the process carried out and to that it is the most efficient robot on the market, the equipment works at speeds from 50 to 400 containers per minute.

- Solid intelligent vision system for future challenges. The strategy followed by Packfeeder for the vision and detection of containers is based on two main factors that help create a solid solution. The superior position of the camera and lighting, instead of using backlight technology. And, the system’s capacity for learning thanks to the advanced software application developed.

- The delicate design of the container’s treatment. Given the origin of Packfeeder in the high cosmetics and personal care industry, the entire process is evaluated to ensure the best treatment and care possible. Different quality tests are done during the adjustments and validation of the equipment in our workshop and also, during the start-up at the customer’s plant. Special finishes, materials and geometries are applied to guarantee the highest quality levels for the most delicate containers.

- Trusted experienced partner. To each of our the solutions, we apply our extensive experience in the packaging machinery industry with 20 years focusing on the container unscrambling. Since the development of the pickFeeder Series robotic range, we have been testing thousands of bottles from previous projects so the technology is fully tested and validated. Proof of this are the big brands that trust our service and our solutions.

There are several reasons that place us as a benchmark in the world of robotic feeding and robotic unscrambles with pucks. One of them is our extensive presence in projects with these characteristics. In addition, the reality is that the number of new projects with this new technology is very high. We have great growth expectations in the short, medium and long term.

We are very satisfied with the contribution we are making to the industry, always in the line of improving production processes.