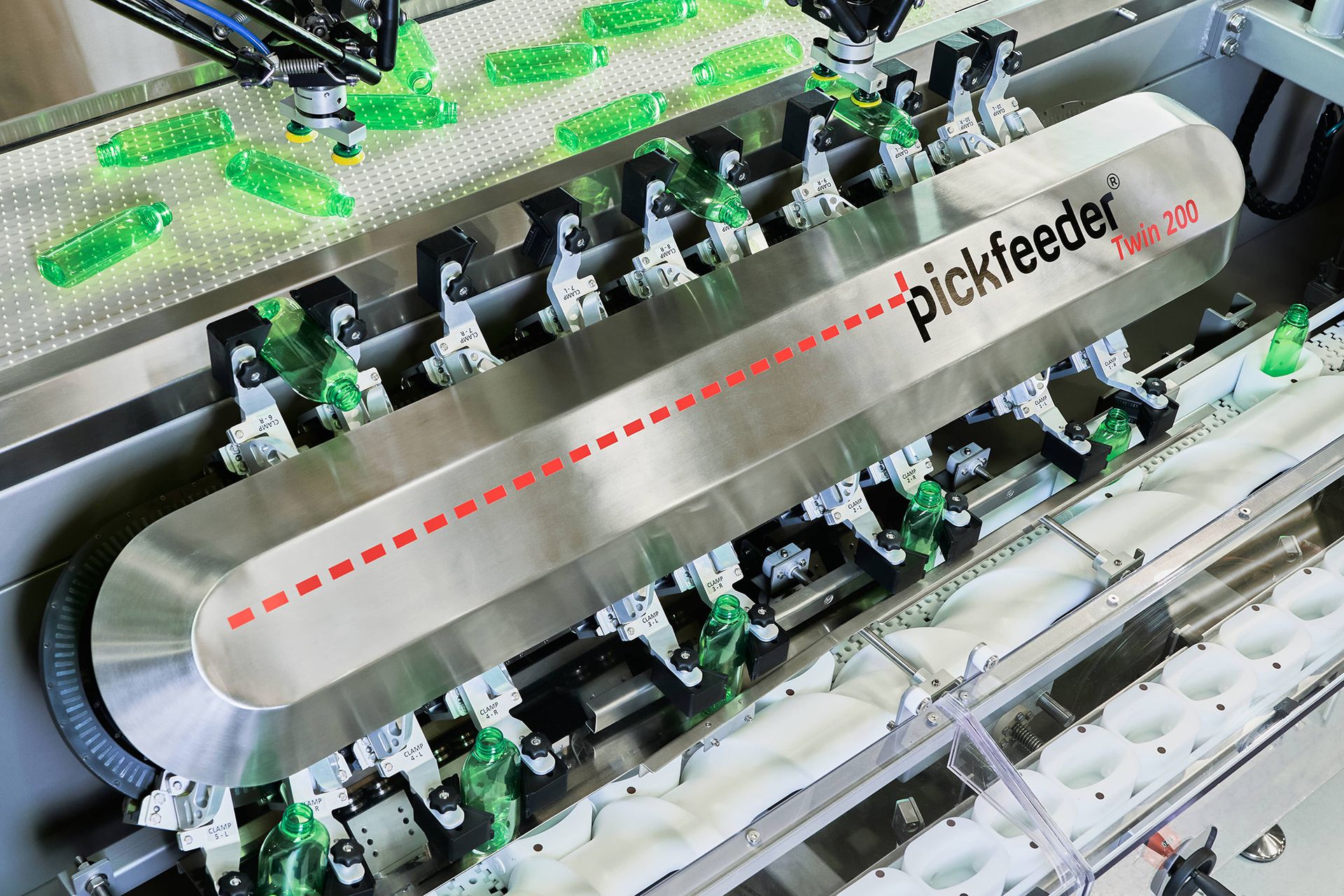

The changing cosmetics and personal care market, with its increasingly complex packaging, demands flexible and efficient packaging solutions. Aware of this evolution, Packfeeder has developed the ‘multiFeeder’

bottle unscrambling concept, an innovative multifunction robotic unscrambler without format changeover that integrates additional functions and materials, optimising production and space.

Flexibility and space efficiency

Based on the patented pickFeeder bottle unscrambling technology, the multiFeeder is born. The cosmetics and personal care industry is facing an increasingly demanding market where customization, data management, traceability and efficiency are key aspects. Floor space is also a critical factor. As the associated costs to every single square meter of clean rooms and productive areas are high.

The multiFeeder allows to integrate additional functions such as orientation of asymmetric bottles, labelling, laser printing, inspection, rejection and puck introduction, all from a single equipment. This modular architecture, thanks to the ease of adaptation of the pickFeeder system, offers great versatility. And allows, the incorporation of other functions according to the specific needs of each customer.

In addition, the system can not only be configured to solve multiple functional needs on a single platform and equipment, but it is also prepared to be multi-material. This means that it can work with containers made of different materials such as plastic, glass, cardboard and its derivatives or aluminium, among others.

The ability to combine multi-function and multi-material capabilities in a single system has allowed the Packfeeder team to configure an extremely versatile platform to meet growing and always changing market demands.

It is undoubtedly an optimal option for the lack of space available in the factory and for reducing the cost of its use, since it is essential that the production lines in the factory take up as little space as possible.

More than just a success story

The multiFeeder equipment shown in this video has been implemented on a client’s line. They have already experienced significant savings in capital investment, use of floor space and process infrastructure.

The elimination of machines on the line thanks to the combination of functions in the multiFeeder has boosted production efficiency at all levels of this personal care products manufacturer.

This is an example of an application where the bottle unscrambler is complemented by the functions of orientation, labelling, laser printing, inspection and rejection. And, finally introduction into pucks for the proper transport towards the filling system.

Also new installations are taking place showing the potential of this hybrid technology capable of sorting multi-materials from the same system and integrating multi-functions in the same process.

See another example of such an application for a German OTC producer:

Multi-sector implementation

The new multiFeeder technology is not limited to cosmetics and personal care indeed. Packfeeder predicts its expansion into sectors such as pharmaceuticals and food, where traceability and product control are becoming increasingly important.

In fact, this new technology will soon be implemented in other multi-sector customers. Who are interested in this combination of functions in the packaging orientation system. This will further consolidate the evolution of the company and its product portfolio.

The multiFeeder represents a leap forward in container unscrambling technology. Offering an integrated, flexible and efficient solution that optimizes production, reduces costs and frees up floor space.

It’s an investment in the future of production. A key to unlocking efficiency, flexibility and profitability in a constantly evolving and changing market.

Want to optimize your packaging line?

At Packfeeder, we provide customized solutions that enhance efficiency and precision in bottle unscrambling.

Contact us so we can review your case together and offer the best option for your packaging line.