In Packfeeder we not only unscramble bottles, but we also orient them.

In today’s packaging industry, there are a multitude of bottle shapes, geometries and finishes that adapt to the different needs. We have the bottle’s shapes that respond to ergonomic functions and needs, usually with indents, handles and other elements for easy grip and handling. And, forms due to reasons related to the product or the marketing strategy, which usually generate label positions and asymmetries of special bodies.

For all this, sometimes it is not enough to have the bottles on the conveyor one after the other and it is also required that they are in a specific orientation. As we have said, there are many reasons why a bottle orienter can be needed, but the most commons are:

- Organic or ergonomic asymmetries in the bottle.

- The label has to be stuck in a specific non-centred position.

- Bottles with handles or indents.

- Bottles with off-centre necks and/or threaded caps that need a specific orientation to pass through the filler and capper.

- The cap or the dispensing pump must be placed in a specific direction, is the case of spray, dispenser or atomiser bottles.

- Containers with semi-transparent windows to measure the level of liquid inside.

Whether due to the characteristics or aesthetics, there are many packaging lines that require a bottle orienter module.

This will be located in most cases at the exit of the bottle unscrambler and before the filler. It can be an independent equipment or it can be integrated into the unscrambler, thus generating a compact and easily integrated monoblock solution.

But, how does the orienting system identify which container must be oriented?

In order to detect in which containers the orientation needs to be corrected, in Packfeeder we use two types of inspection systems. On the one hand, the photocell reading system, which would be the most basic. It allows to identify those bottles that present a clear lateral asymmetry in their shape or profile, useful in low or medium production speed applications. On the other hand, when the application requires it, an artificial vision camera system that allows total effectiveness against any asymmetry and at any production speed is installed, providing greater flexibility and versatility. In short, depending on the requirements and needs of the bottles of a packaging line, one system or another will be chosen.

1 equipment 2 functions

Aware of space limitations and the need of our customers to simplify and group functions in their lines, the Packfeeder’s bottle orientation modules are integrated into our unscramblers. Installing a combined system, the space occupied and also the costs are being reduced. In addition, if the turning tools of the bottles have to be changed, as with our container sorters, we have a format change without adjustments, without tools and totally manual for lines that work with various formats, saving time and avoiding stoppages in production. We currently have two ranges of unscramblers in which we integrate the bottle orientation function:

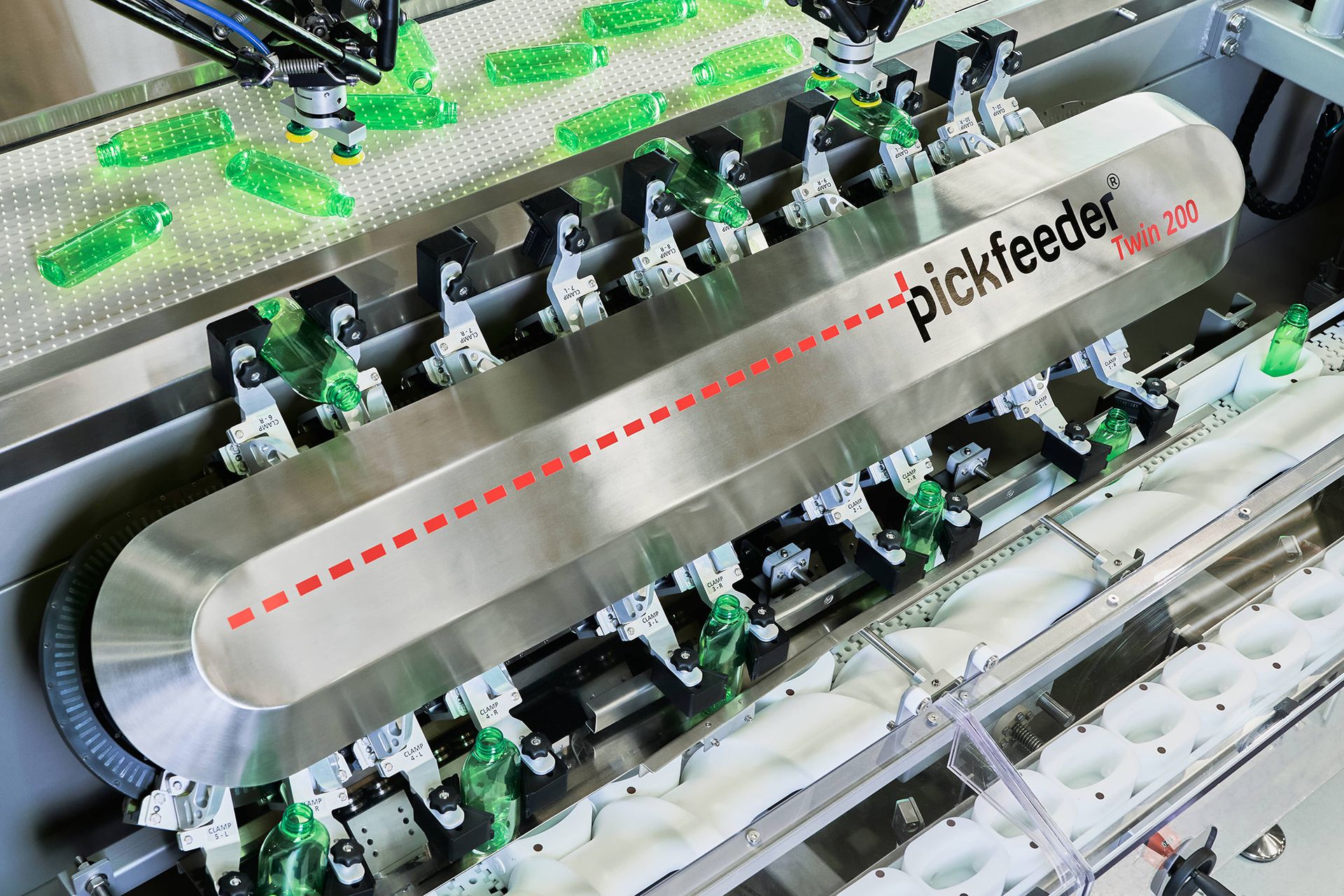

The InLine Series range, consisting of mechanical positioners with the bottle orientation module integrated, in a monoblock. The shown equipments in both videos belong to this range.

And, the Pickfeeder Series robotic range, that thanks to its design and the use of innovative technologies, results in an extremely flexible solution that does not need an additional orientation module. The robots are configured to only pick up the correctly oriented bottles. So, orientation is no longer a concern with this robotic sorter.

In Packfeeder we aim to adapt to the needs of any packaging line, that is why we offer complementary solutions compatible with our unscramblers. All our equipments have the ability to work and orient containers introduced into pucks or into a transporter. We also have solutions for environments with high hygiene requirements thanks to our bottle cleaning systems. And, as one of our priorities, we always guarantee the care and delicate treatment of the container in every moment.

Our bottle unscramblers adapt to the demands of any packaging line. Either because you want to know more, because you need a bottle orienter or any other solution, do not hesitate to contact us.