PHARMA

INDUSTRY

The quality you need

for your packaging lines

for your packaging lines

INDUSTRY FOCUSED

TECHNOLOGY

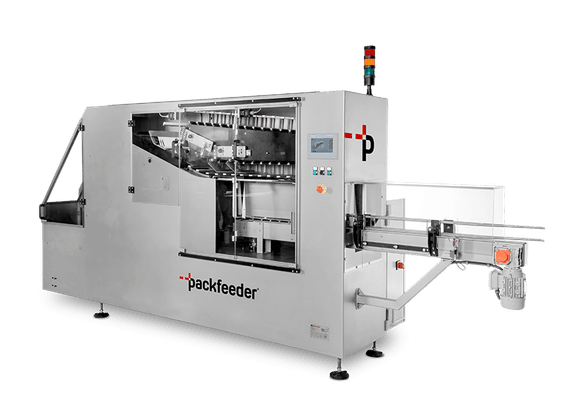

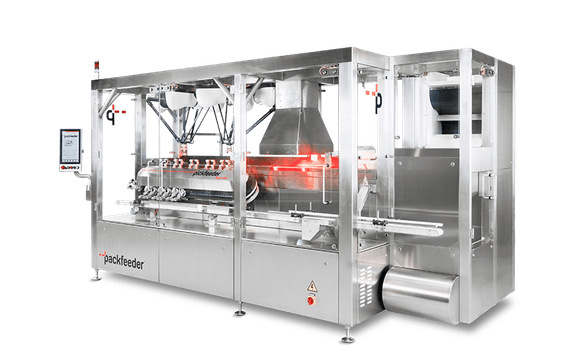

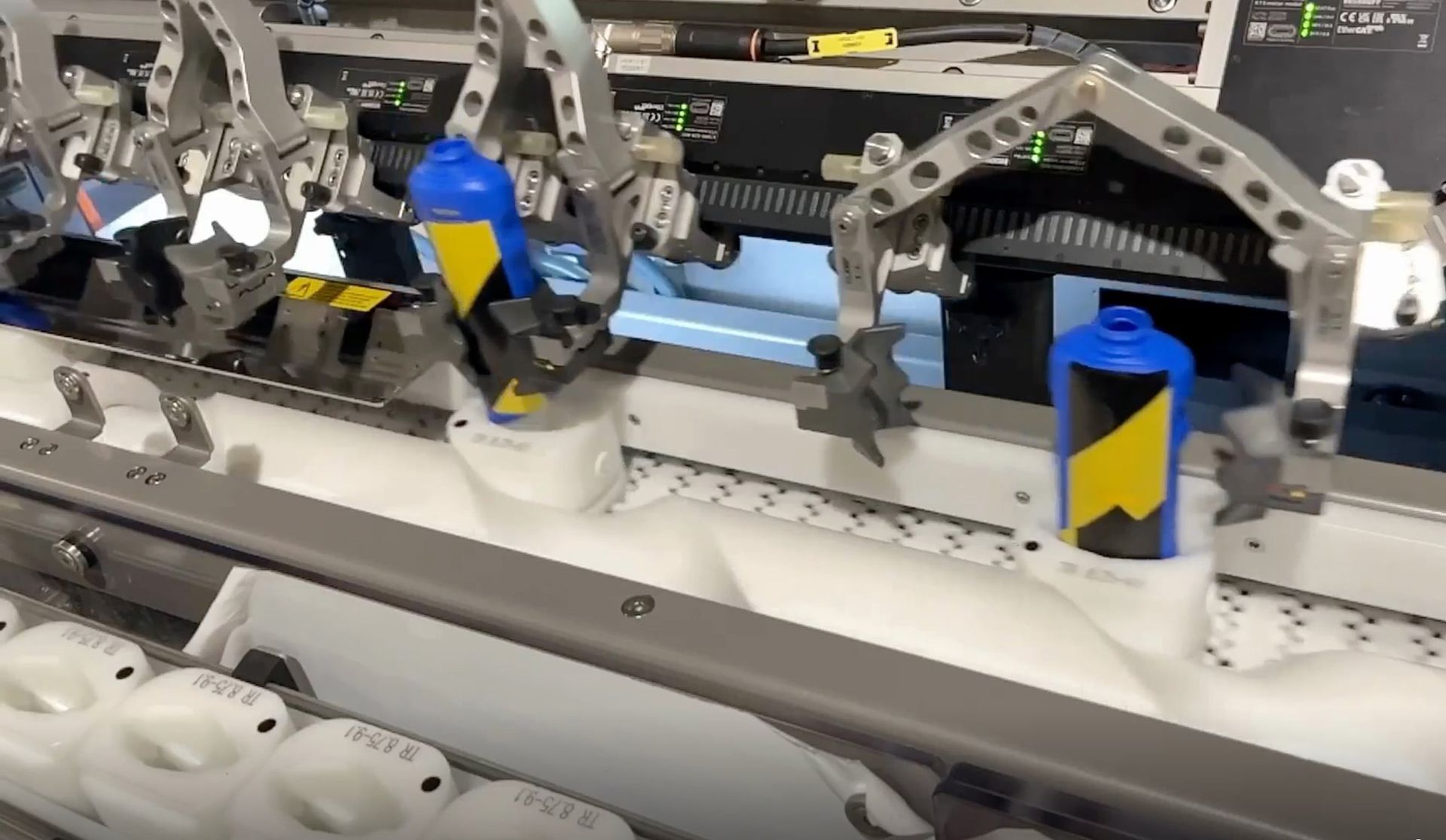

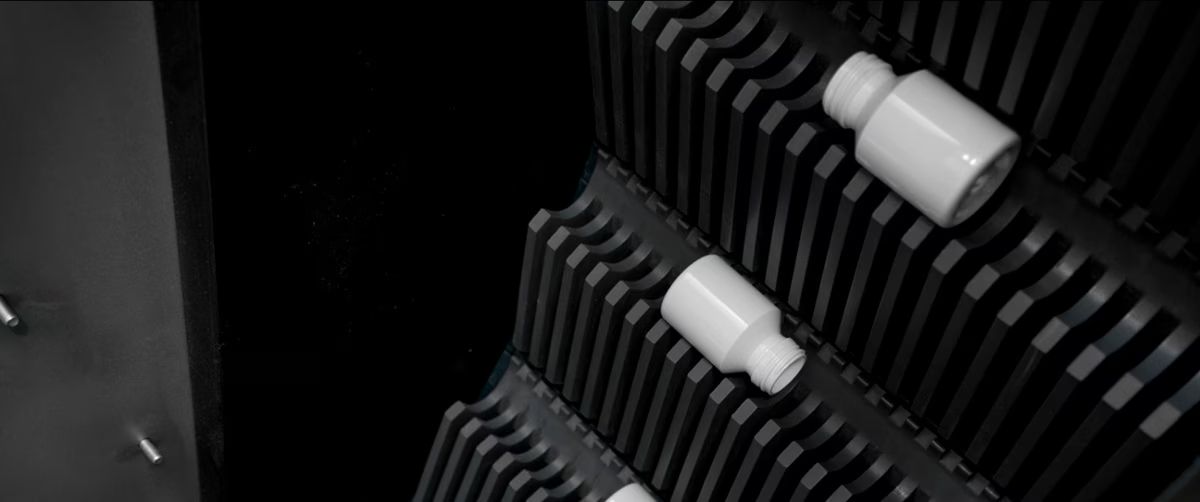

Packfeeder plastic container unscrambling and orientation systems are a key element in pharmaceutical production lines. Our bottle feeders are extremely compact, clean and low-noise. These features, combined with gentle package handling, ensure compliance with the highest standards required by the pharmaceutical industry. And where needed, validation and traceability protocols are implemented that are highly valued in this industry.

SOLUTIONS

SORTING TECHNOLOGY

MUCH MORE

THAN UNSCRAMBLING

CLEANING SYSTEMS

TRACK & TRACE

INSPECTION

LASER CODING

INKJET CODING

LABELLING

ORIENTATION