COMPLEMENTARY

SOLUTIONS

We do much more than unscrambling.

We can supply the needed function for each line and package.

We can supply the needed function for each line and package.

ORIENTATION

Whether the container has handles, serigraphy or geometries that make it asymmetrical, our systems meet the orientation needs of any line.

This solution can be integrated with other functions as a puck loader, keeping the design simplicity and the user-friendliness of the equipment.

Thanks to its compact design, it requires very little additional space.

Thanks to its compact design, it requires very little additional space.

PUCK INTRODUCTION

Whenever required due to unstable or delicate containers, or even for working with a multiformat line, a puck loading system can be integrated into the bottle unscrambler.

Our equipment is compact and requires very little additional space.

Without the use of additional sensors, we guarantee that 100% of the pucks coming out of the machine are filled with bottles.

We can work with closed or open pucks of any geometry and also adapt to an existing puck system.

Without the use of additional sensors, we guarantee that 100% of the pucks coming out of the machine are filled with bottles.

We can work with closed or open pucks of any geometry and also adapt to an existing puck system.

CLEANING SYSTEMS

Integrate cleaning and unscrambling functions in one system. We adapt to the required hygiene level of each line.

The clean technology and absence of airborne particles means we can meet the stringent requirements of industries such as pharmaceutical and food.

LABELLING

For production lines requiring precise label application, a fully integrated labeling system can be added to your unscrambling process.

Our labeling equipment is designed to be compact, saving valuable space on the production floor.

Ensure consistent label placement for enhanced brand image. We are capable of working with a wide range of label sizes and materials, and can easily adapt to both new and existing packaging lines.

Ensure consistent label placement for enhanced brand image. We are capable of working with a wide range of label sizes and materials, and can easily adapt to both new and existing packaging lines.

LASER CODING

The accuracy of the printing ensures that each bottle is correctly coded with essential information such as batch numbers, expiry dates and barcodes.

This module is designed to provide high-resolution markings on a variety of bottle materials, including glass, plastic and metal. Its precision ensures that codes are legible and durable, meeting industry standards.

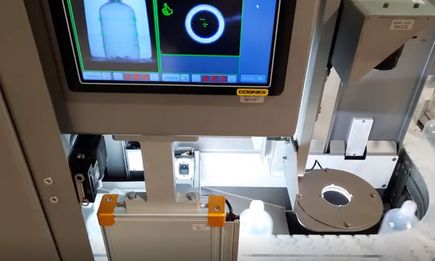

INSPECTION

Guarantee product quality and enhance your production line by integrating an inspection module into your bottle unscrambler.

Designed to fit seamlessly into your equipment, this module provides real-time monitoring and analysis.

By automating the inspection process together with a rejection system, you can significantly increase your production speed while maintaining high quality standards.

By automating the inspection process together with a rejection system, you can significantly increase your production speed while maintaining high quality standards.

TRACK & TRACE

Our bottle unscramblers can be equipped with a state-of-the-art Track&Trace module, suitable for printing & verification, coding, and serialization, among other critical functions.

With this integrated system, you can track every bottle from production to the consumer, ensuring complete transparency and accountability at every stage.

Implementing end-to-end product tracking provides complete supply chain visibility, allowing you to monitor and manage your products seamlessly.

Implementing end-to-end product tracking provides complete supply chain visibility, allowing you to monitor and manage your products seamlessly.

INKJET CODING

With the integrated inkjet capability, you can apply codes to maximise throughput and ensure your production process remains fast and efficient.

This system allows you to apply a variety of codes and marks for product identification, bringing flexibility and reliability to your operations. Whether you need to print batch numbers, sell-by dates or other important information, our bottle positioner ensures that every bottle is accurately marked.